When we talk about recycling auto parts, we're referring to the process of taking cars that have reached the end of their road and giving them a new purpose. It's about systematically dismantling these vehicles, saving every component that still has life in it, and reclaiming valuable raw materials like steel and aluminium to be used again.

This whole process turns what would otherwise be automotive waste into a genuine resource, which is a massive win for cutting down our reliance on landfills. It's not just great for the environment; it also offers some serious financial benefits for car owners.

Unlocking the Value in End-of-Life Vehicles

Picture a car at the end of its life. Don't see it as a hunk of scrap metal, but as a treasure chest of valuable resources waiting to be opened. That’s the mindset behind the auto parts recycling industry. Instead of letting old vehicles just sit and rust away, a methodical process is used to extract every last bit of value.

It's about breathing new life into old parts and raw materials, turning potential waste into an economic and environmental asset. This isn't just about crushing cars; it's a highly organised operation that kicks off the moment a vehicle is officially retired. From that point, it heads to a specialised facility where it's carefully taken apart. The aim is simple: salvage what works and reclaim what can be remade.

From the Road to Resource Recovery

The journey from a retired car to a collection of ready-to-use parts has a few key steps. Think of it less like a chaotic wrecking yard and more like an organ donation system for cars. Every part is carefully checked to see if it’s got a second life in it.

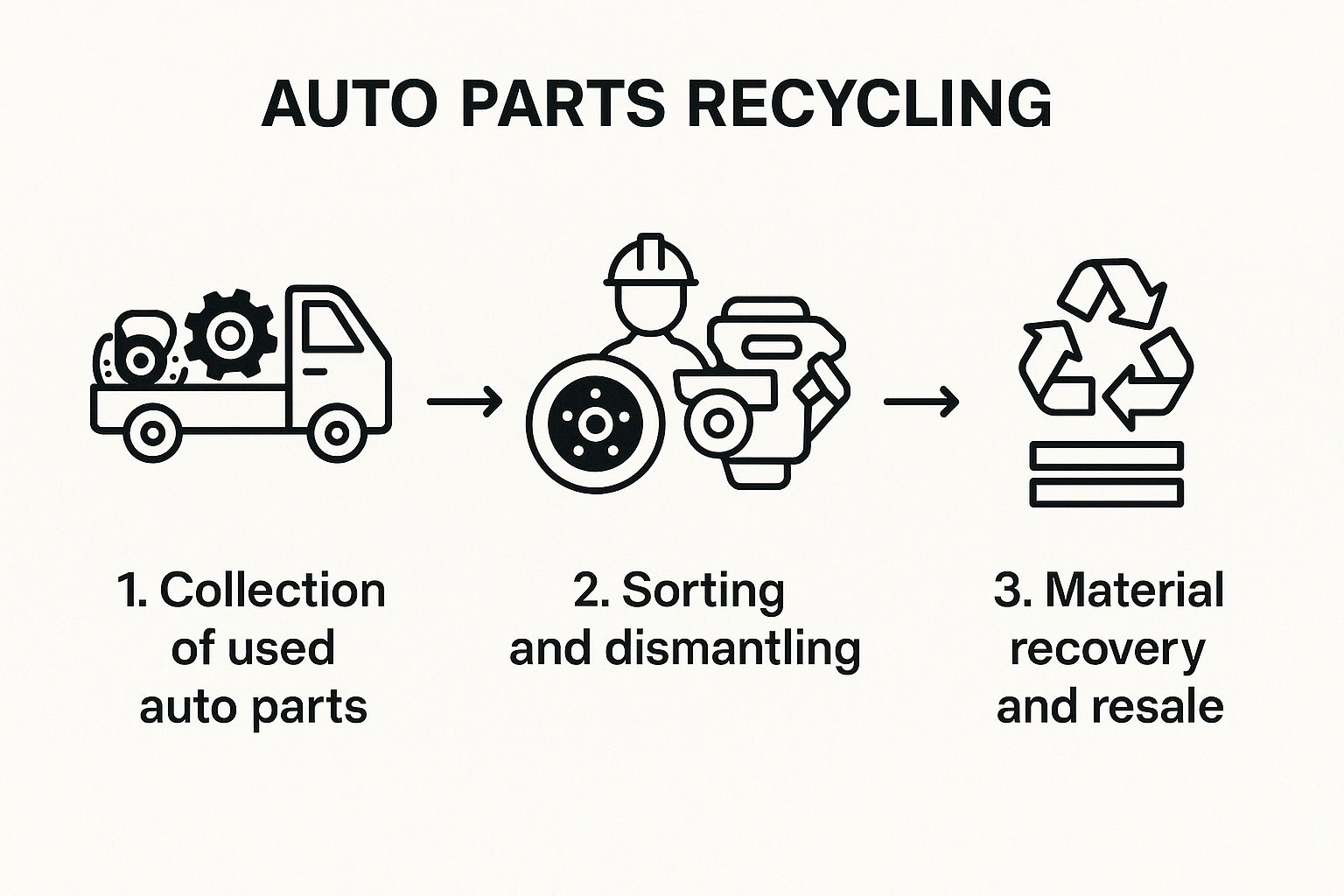

The process usually looks something like this:

- Careful Dismantling: Technicians are strategic here. They remove the functional, high-demand parts first—things like engines, transmissions, alternators, and even body panels.

- Thorough Inspection: Every single salvaged component goes through a tough inspection and testing process to make sure it’s safe and performs as it should.

- Digital Cataloguing: Once a part gets the green light, it's cleaned, catalogued, and logged into a digital inventory. This makes it incredibly easy for mechanics and everyday car owners to find exactly what they need.

- Material Reclamation: The car's shell, now stripped bare, is processed to separate and recover the raw materials. We're talking steel, aluminium, copper, and plastics.

This kind of organised approach is crucial for Australia's environmental health. Each year, around 850,000 vehicles are retired down under, which adds up to roughly 1.36 million tonnes of waste. Our local industry does a decent job of recovering a lot of this, but we've still got a way to go to catch up with global best practices. If you're interested in the details, you can explore the new report that reveals how to improve car recycling in Australia.

When we fully embrace the auto parts recycling model, our perspective shifts from just disposing of waste to seeing an opportunity. Every recycled alternator, every kilogram of reclaimed steel, and every reused side mirror is a win for resource conservation.

Ultimately, this industry gives us a smart, sustainable option instead of always manufacturing new parts from scratch. It conserves our natural resources, slashes energy consumption, and stops millions of tonnes of waste from clogging up our landfills. It’s solid proof that a car's final stop can actually be the start of a whole new journey.

The Environmental Impact of Recycling Car Parts

When you choose a recycled car part, you're setting off a powerful, positive ripple effect for the environment. It's a decision that goes far beyond a simple repair; it actively reduces the strain on our planet’s finite resources. The benefits aren't just abstract ideas—they are tangible, measurable improvements that help protect Australia's natural beauty.

Think about what it takes to manufacture a brand-new car part, say an alternator. The journey starts with mining for ore, a process that scars the landscape and burns through immense amounts of energy. Those raw materials are then shipped, often across continents, before being smelted and shaped in energy-intensive factories. Every single step leaves a significant carbon footprint.

Opting for a recycled alternator means you get to bypass that entire destructive cycle. The part already exists. Recovering it uses just a fraction of the energy, dramatically cutting greenhouse gas emissions and preserving precious raw materials that would otherwise be torn from the earth. That one choice is a direct contribution to a more sustainable future.

Conserving Energy and Natural Resources

The energy savings from recycling auto parts are genuinely staggering. It’s an energy-hungry process to create new car parts from scratch. Smelting metals like steel and aluminium, for example, requires enormous amounts of electricity, much of which still comes from burning fossil fuels.

Recycling these same metals, on the other hand, is far more efficient. Recycling steel, for instance, uses about 74% less energy than producing it from raw iron ore. For aluminium, the savings are even more impressive, climbing as high as 95%. This huge drop in energy demand means fewer harmful emissions are pumped into our atmosphere.

By choosing a recycled component, you are directly preventing the need for new mining operations. This helps conserve our natural landscapes, protect wildlife habitats, and reduce the water and air pollution tied to extracting and processing virgin materials.

Every recycled part also represents a smart conservation of the metals and minerals themselves. Resources like platinum, palladium, and rhodium—found in catalytic converters—are rare and finite. Recycling ensures these valuable elements can be put back to work, lessening our reliance on environmentally damaging mining practices.

Preventing Landfill and Soil Contamination

When a vehicle is simply dumped, it becomes a long-term environmental liability. End-of-life vehicles are filled with a cocktail of hazardous materials that can cause serious harm if left to decay in a landfill.

Proper auto parts recycling is, first and foremost, a depollution process. Before any parts are salvaged for reuse, trained technicians methodically drain all the dangerous fluids from the vehicle. This includes things like:

- Engine Oil: Highly toxic and capable of contaminating huge volumes of soil and groundwater.

- Antifreeze (Coolant): Contains ethylene glycol, a substance that is poisonous to both animals and humans.

- Brake and Transmission Fluids: These can contain heavy metals that are incredibly harmful to local ecosystems.

- Battery Acid: A highly corrosive substance that can leach lead and other toxins straight into the environment.

By safely containing and properly managing these substances, the auto parts recycle industry stops them from seeping into Australian soil and waterways. It’s a crucial step in protecting our local ecosystems and agricultural land from contamination. Even tricky items like tyres, which can take centuries to decompose while releasing harmful chemicals, are managed responsibly. To learn more about that specific challenge, our guide on the safe https://autoremovaladelaide.com.au/disposal-of-tyres/ offers a much deeper look.

This careful, systematic management transforms what could be an environmental disaster into a clean, valuable resource.

The table below breaks down just how significant the environmental savings are when you choose recycled parts over new ones. It’s a clear illustration of the positive impact you can make.

Environmental Impact of New vs Recycled Auto Parts

| Component | New Part Environmental Cost (Estimated) | Recycled Part Benefit |

|---|---|---|

| Steel Body Panel | Involves mining iron ore, coal; high energy use for smelting; significant CO2 emissions. | Saves ~74% of the energy; conserves ore; reduces air and water pollution from mining. |

| Aluminium Wheel | Bauxite mining is highly destructive to landscapes; refining is extremely energy-intensive. | Uses ~95% less energy than primary production; drastically cuts greenhouse gas emissions. |

| Battery | Mining for lead and lithium; contains hazardous acids and heavy metals. | Prevents lead and acid from contaminating soil and water; recovers valuable, finite materials. |

| Alternator | Requires copper, steel, and aluminium; mining and manufacturing leave a large carbon footprint. | Conserves metal resources; avoids the energy and pollution costs of manufacturing a new unit. |

As you can see, the choice to use a recycled part isn't a small one. It adds up to massive savings in energy, a reduction in pollution, and the preservation of our natural resources for future generations.

How Recycled Parts Create Major Financial Savings

Let's be honest, car repairs are never welcome news, and the cost of brand-new, original (OEM) parts can turn a minor issue into a major financial headache. This is where choosing recycled parts isn't just a smart move for the planet—it's one of the best things you can do for your wallet.

Opting for recycled parts gives you access to high-quality, reliable components for a fraction of the cost. The savings aren't just pocket change, either. We're talking about a significant reduction in your repair bills, and it all comes down to one simple fact: the part has already been made.

Bypassing the High Cost of New Parts

Think about what it takes to produce a new car part. The whole process is a long and expensive chain of events. It starts with mining raw materials, shipping them to factories (often on the other side of the world), and then running energy-hungry machinery to manufacture the final component.

Every single step adds to the price you pay at the counter:

- Raw Material Costs: Sourcing all the metals, plastics, and rubber needed.

- Manufacturing: The huge cost of energy, machinery, and labour to forge, mould, and assemble everything.

- Shipping & Logistics: Moving the finished part from the factory, to a warehouse, to your local supplier.

- Marketing & Branding: All the overheads that come with selling a new OEM product.

A recycled auto part neatly sidesteps this entire supply chain. Because the part already exists, the only real costs are in the careful removal, inspection, and cataloguing. It’s a much more direct and efficient process, and those savings get passed straight on to you.

What This Means for Your Repair Bills

So, how much can you actually save? The difference becomes incredibly clear when you look at common repairs. For many people, the choice between a new or recycled part is the difference between an affordable fix and having to make a tough decision about the car's future.

The numbers really speak for themselves. Recent research found that the average Aussie driver could save around $2,144 over five years just by choosing recycled components. When you scale that up, it’s a potential nationwide saving of $15.5 billion! It’s no surprise that 82% of Australian vehicle owners are open to buying recycled parts—the value is undeniable.

This isn't just about getting a discount. It's a smarter way to manage the ongoing cost of owning a vehicle. You keep your car running safely without emptying your bank account.

The table below gives you a clearer idea of the savings on some typical repairs. And if you're interested in learning more, our look into the benefits of recycling automotive parts goes into even more detail.

Price Comparison: New vs. Recycled Parts

| Common Repair | New OEM Part (Estimated Cost) | Recycled Part (Estimated Cost) | Potential Savings |

|---|---|---|---|

| Gearbox Replacement | $3,500 – $6,000 | $800 – $2,000 | Up to 70% |

| Alternator Replacement | $600 – $1,200 | $150 – $400 | Up to 65% |

| Side Mirror Assembly | $300 – $700 | $75 – $200 | Up to 75% |

| Starter Motor | $450 – $900 | $100 – $300 | Up to 70% |

As you can see, the recycled option delivers massive savings every time without cutting corners on quality. You’re getting a genuine part made for your car's specific make and model, just at a much more reasonable price. At the end of the day, it proves that the most environmentally friendly choice is also the most economically intelligent one.

Inside the Auto Parts Recycling Process

Forget the old image of a chaotic, greasy junkyard. Modern auto recycling is a clean, systematic, and surprisingly sophisticated operation. Think of it less as a graveyard for cars and more as a deconstruction line, meticulously designed to safely recover every last bit of value.

This precise workflow transforms a retired car from a potential environmental liability into a treasure trove of reusable parts and raw materials. It's a process that blends hands-on mechanical skill with a deep commitment to environmental responsibility, making sure nothing goes to waste. Let's walk through the five key stages that make this remarkable transformation happen.

This visual shows that modern auto recycling isn’t a one-way trip to the landfill. It's a structured, circular process designed to keep valuable resources in play.

Stage 1: Depollution and Fluid Removal

Before a single bolt is turned, the first and most crucial step is depollution. A car is essentially a mobile container of hazardous fluids, and getting them out safely is priority number one. The vehicle is moved to a specialised draining bay where technicians methodically remove every last drop.

This includes:

- Engine oil and coolant

- Transmission and brake fluid

- Petrol or diesel from the fuel tank

- Refrigerants from the air conditioning system

Each fluid is drained into its own sealed container. This prevents any cross-contamination and ensures everything can be recycled or disposed of according to strict environmental laws. It’s this step that stops countless litres of toxic substances from ever contaminating Australian soil and waterways. The car's battery, full of corrosive acid and heavy metals like lead, is also carefully removed at this point.

Stage 2: Strategic Dismantling

With the vehicle now clean and safe, the real dismantling begins. This is where skilled technicians act like surgeons, carefully harvesting the parts that have a second life ahead of them. They focus on high-demand components known for their reliability, the ones mechanics and car owners are always looking for.

This isn't just a free-for-all with a spanner. It's a planned operation, with parts removed in a specific order to avoid damaging other valuable pieces. For example, the engine and transmission—two of the most valuable assemblies—are often pulled out as a single unit. Other hot-ticket items include alternators, starter motors, radiators, and undamaged body panels like doors and bonnets.

This stage is the heart of the auto parts recycle business model. It's where the economic value is truly unlocked, creating a steady supply of affordable, genuine parts for the repair industry.

Stage 3: Quality Assurance and Testing

A salvaged part is worthless if you can't trust it. That's why every single component pulled from a vehicle goes through a rigorous quality assurance process. It’s not enough for a part to just look good; it has to be proven to work correctly and safely.

Technicians meticulously inspect each item for signs of excessive wear, cracks, or damage. After the visual check, mechanical and electrical parts are put on the test bench. An alternator will be checked to make sure it's putting out the right voltage, while a gearbox is tested for smooth shifting and operation.

Only after passing these strict checks does a part get the green light for resale. This commitment to quality control is what allows reputable recyclers to back their parts with a warranty, giving you complete peace of mind.

Stage 4: Digital Inventory and Warehousing

Once a part is tested and certified, it's prepped for its new life. It gets a thorough cleaning, is assigned a unique stock number, and is photographed from multiple angles. All the critical details—the make, model, year, and even the VIN of the car it came from—are logged into a sophisticated digital inventory system.

This computerised database is the modern-day wrecking yard's bible. It lets staff (and often customers online) instantly search for a specific part and confirm its availability and compatibility. The part is then tagged and stored in a huge, organised warehouse, ready to be picked and shipped the second an order is placed.

Stage 5: Material Recovery and Shredding

After all the reusable parts have been carefully salvaged, the empty shell, or "hulk," is all that's left. But its journey isn't over yet. This shell is still packed with valuable raw materials. The hulk is fed into a massive industrial shredder that rips it into fist-sized pieces of metal in just a few seconds.

From there, a combination of powerful magnets and advanced sensors gets to work sorting the shredded material. Ferrous metals like steel are yanked out by the magnets, while other systems separate non-ferrous metals like aluminium and copper. These raw materials are then cleaned, compacted, and shipped off to smelters to be melted down and reborn as new products, completing the recycling loop.

A vehicle is far more than just steel. The table below breaks down the rich mix of materials recovered from the average car, highlighting just how much we can save from landfill.

Recyclable Materials Recovered from an Average Vehicle

| Material | Approximate Percentage by Weight | Common Recycled Uses |

|---|---|---|

| Steel & Iron | ~65% | New car bodies, construction beams, appliances |

| Aluminium | ~10% | Engine blocks, wheels, new drink cans |

| Plastics | ~8% | New car parts, carpets, insulation |

| Rubber | ~5% | Playground surfaces, athletic tracks, new tyres |

| Glass | ~3% | New windows, bottles, fibreglass |

| Other Metals | ~3% | Copper wiring, lead from batteries, zinc coatings |

| Fluids & Oils | ~6% | Re-refined into new lubricants or industrial fuel |

This breakdown shows that nearly every part of a car can be repurposed. By recovering these materials, we not only conserve natural resources but also save a massive amount of energy compared to producing them from scratch.

Finding a Reputable Auto Recycling Service

Deciding to use a recycled car part is a smart move for your budget and the planet. But that’s only half the job. The real challenge is finding a trustworthy supplier who genuinely stands behind what they sell. A reputable auto parts recycle service isn’t just selling secondhand bits; they’re offering you confidence and peace of mind.

It’s a bit like picking a good mechanic. You’re looking for someone with solid experience, who is upfront and honest, and has the right setup to do the job properly. In the world of auto recycling, this translates to having the right certifications, offering clear warranties, and running an organised yard that ensures you get the exact part you need.

It can seem daunting at first, but a few tell-tale signs will quickly help you sort the pros from the backyard operations.

What to Look For in a Supplier

Your main goal is to find a business that treats recycled parts with the same level of care as new ones. You can spot a professional outfit by how they manage their stock, talk to customers, and back up their products. You're looking for clear evidence that they're a legitimate, well-run operation.

Here are the key things you should be checking for:

- Industry Certifications: Keep an eye out for memberships in industry bodies like the Auto Parts Recyclers Association of Australia (APRAA). This is a strong signal they’re committed to high standards.

- A Modern Inventory System: A proper recycler uses a computerised, searchable inventory. This means they can pinpoint the right part for your car's make, model, and year in moments, taking all the guesswork out of the equation.

- Clean and Organised Premises: A tidy, well-organised yard or warehouse is a dead giveaway of a professional business. It shows they take pride in their work and look after their parts.

Running through this quick checklist helps you filter out the noise and focus on businesses that are serious about quality. If you're wondering where to start, this guide on finding an auto recycle service near me is a great resource.

Verifying Part Quality and Compatibility

Let's be honest, the biggest worry for most people is whether a used part is going to last. A top-notch recycling service gets this, and they’ll be completely transparent about how they test and grade their stock. They should have no problem telling you exactly what they do to ensure quality.

Don't be shy about asking direct questions on how a specific part was tested. A trustworthy supplier will actually appreciate your attention to detail and will happily walk you through their quality assurance process. That kind of transparency is what a confident purchase is built on.

It can also be helpful to see the standards set by related industries, such as Australia's best construction machinery parts suppliers, to get a feel for what constitutes excellent service and quality control across the board.

Before you hand over any money, make sure you get straight answers to these four crucial questions:

- "What is your testing process for this specific part?" For something like an alternator, they should confirm it was bench-tested to ensure it puts out the correct voltage. For a gearbox, they should be able to tell you it was checked for smooth operation.

- "What is the part's history?" Good suppliers often log the Vehicle Identification Number (VIN) and the kilometres from the donor car. This gives you invaluable insight into the part's past life.

- "What is your warranty policy?" This is a deal-breaker. A decent supplier will always offer a warranty, usually somewhere between 30 days and a full year. Get the terms in writing so you know exactly what’s covered.

- "What is your return policy if the part is incorrect?" Mistakes happen. A professional business will have a fair and simple return policy if they accidentally give you the wrong part, ensuring you aren’t left stuck with it.

Asking these questions puts you in control. It helps you confirm the part’s condition and make a smart choice that saves you money without risking safety or reliability. A supplier who can answer these questions without hesitation is one you can probably trust.

The Future of Automotive Plastics Recycling

Look inside any modern car, and you'll find plastic everywhere – dashboards, bumpers, fuel tanks, you name it. These materials are brilliant for making vehicles lighter and more fuel-efficient, but they’ve always been a massive headache for the auto parts recycle industry. Unlike metal, which is pretty straightforward to recover, car plastics are a jumble of different polymers, making them a real challenge to separate and reuse.

But that challenge is quickly turning into a story of incredible innovation. The future of automotive recycling is being shaped by new technologies designed to tackle these complex materials head-on. This isn't just about keeping plastic out of landfill; it's about transforming a tricky waste stream into a valuable resource for a circular economy.

Innovations in Plastic Sorting and Reprocessing

The real secret to unlocking the value in all that automotive plastic is simply getting better at sorting it. Cutting-edge facilities are now deploying some seriously clever methods to separate different types of polymers with pinpoint accuracy.

Here's a glimpse at the tech making it happen:

- Near-Infrared (NIR) Spectroscopy: Think of this as a high-speed scanner for plastic. It uses light to instantly figure out the chemical makeup of each piece, allowing automated systems to sort different types at an incredible pace.

- Density Separation: It’s a bit like panning for gold, but for plastics. Since different polymers have different densities, they can be separated by floating or sinking them in specially prepared liquid baths.

- Chemical Recycling: This is the real game-changer. These advanced processes break plastics right down to their original molecular building blocks. From there, they can be used to create brand-new, virgin-quality plastics, perfect for manufacturing the next generation of car parts.

What this means is that a dashboard from a car that's a decade old can genuinely be transformed into a core component for a brand-new vehicle.

By mastering the art of plastic recovery, the auto recycling industry is closing a critical loop in the manufacturing cycle. It’s a powerful demonstration of how end-of-life vehicles can fuel the creation of the next generation of cars.

This isn’t just an environmental pipe dream, either; it’s a booming economic sector right here in Australia. The recycled plastic market is forecast to nearly double, jumping from around USD 869.1 million in 2025 to a projected USD 1.58 billion by 2032. That growth is being fuelled by the massive demand for sustainable materials from manufacturers, including our own auto industry. You can dig into the numbers on Australia's recycled plastic market growth to see the full picture.

As we shift towards electric vehicles, the focus on recovering every last bit of material is only going to grow stronger. To get a better sense of how EV batteries fit into this picture, it's worth exploring discussions on the future of sustainable EV battery management. These forward-thinking solutions are cementing auto recycling's role as an essential tool for a sustainable future.

Got Questions About Recycled Auto Parts?

Even when you know about the environmental and financial perks, it's smart to have a few questions before fitting your car with recycled components. Let’s clear up some of the most common queries so you can make your choice with total peace of mind.

Are Recycled Auto Parts Actually Safe and Reliable?

This is the big one, and the answer is a definite yes—as long as you’re buying from a reputable professional. A proper auto parts recycler doesn't just pull a part off a wreck and stick it on a shelf.

Every single component goes through a rigorous inspection process. They’re tested to make sure they meet the original equipment manufacturer (OEM) standards for both performance and safety. A good supplier stands behind their parts because they’ve done the work to verify their quality, meaning you can trust that alternator or body panel.

How Can I Be Sure a Part Will Fit My Car?

These days, professional auto recyclers use incredibly detailed, computerised inventory systems. When a vehicle comes in, every salvageable part is catalogued against the car's make, model, year, and often its Vehicle Identification Number (VIN).

This meticulous data tracking removes all the guesswork. Just give the supplier your car's details, and their system will pinpoint the exact part designed for your vehicle. It guarantees a perfect fit.

A common myth is that 'used' means 'worn out'. The reality is quite different. Many parts are salvaged from newer, low-kilometre cars that were written off for cosmetic or structural reasons. Their mechanical and electrical systems are often still in near-new condition.

What Sort of Warranty Should I Expect?

Any professional recycler worth their salt will back their parts with a warranty. The specific terms can differ from place to place, but you should expect to see coverage ranging anywhere from 30 days to a full year.

This warranty is their vote of confidence in the part's quality and your assurance that it's built to last. Always make sure you get the warranty details in writing before you hand over any money.

Are you looking to get rid of an old, broken, or unwanted vehicle cluttering up your space? At Auto Removal Adelaide, we offer top cash prices and provide free scrap car removal services across the Adelaide area. Turn your junk car into instant cash today by visiting https://autoremovaladelaide.com.au.